IoT systems are transforming industries by enabling real-time monitoring and control of processes, unlocking unprecedented levels of efficiency and performance optimization across manufacturing, energy, and logistics sectors.

🚀 The Revolution of Real-time Flow Management

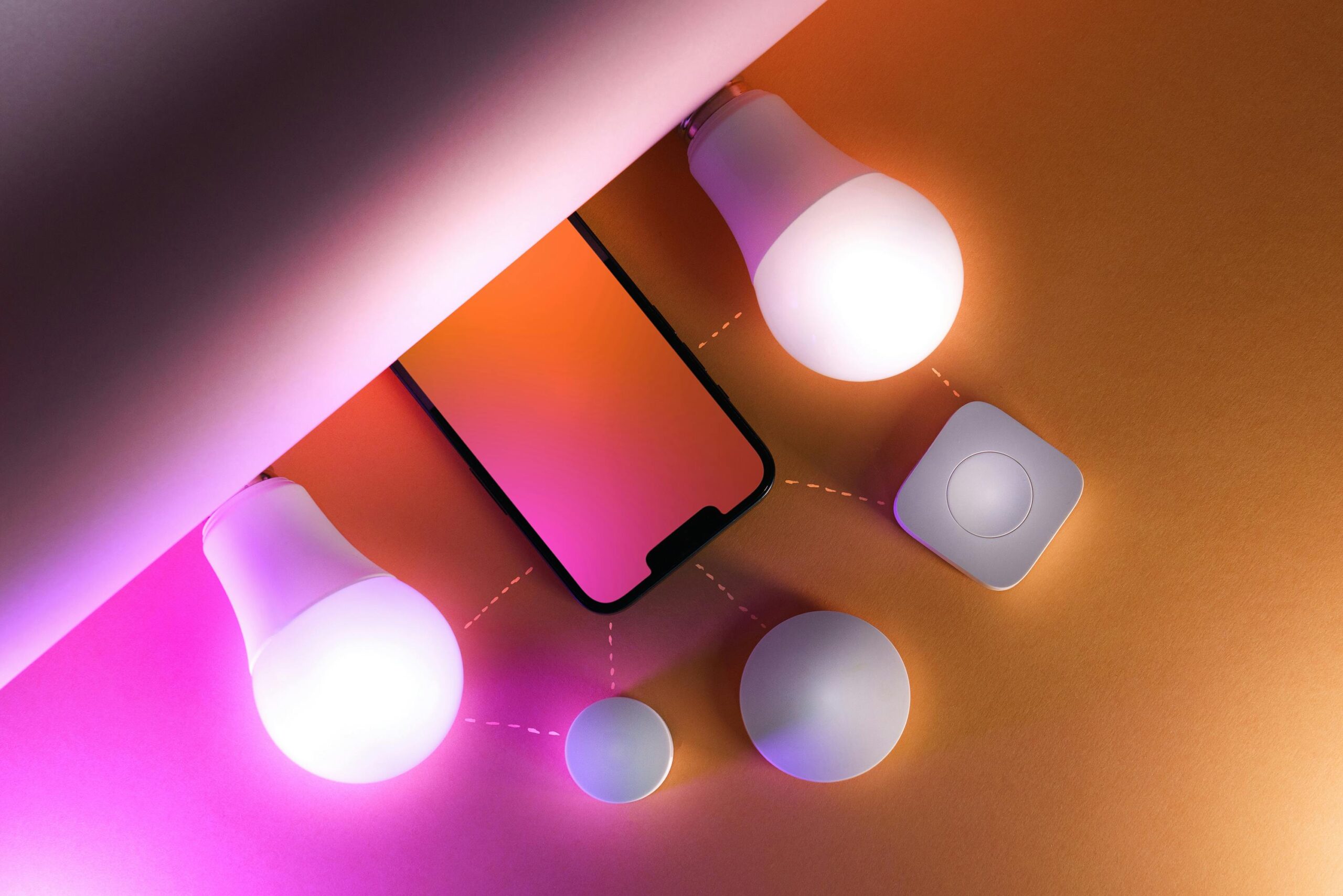

Modern industrial operations demand continuous adaptation to changing conditions. Traditional flow management systems relied on periodic manual adjustments, creating inefficiencies and delays that cost businesses millions annually. The integration of Internet of Things (IoT) technology has fundamentally changed this paradigm, enabling organizations to monitor and adjust operational flows instantaneously based on live data feeds from connected sensors and devices.

Real-time flow tuning represents a sophisticated approach to process optimization where IoT sensors continuously collect performance data, analyze patterns, and automatically adjust parameters to maintain optimal operating conditions. This dynamic methodology eliminates the lag time between problem detection and resolution, significantly reducing waste, energy consumption, and operational costs while maximizing output quality and consistency.

Understanding the Core Components of IoT Flow Systems

Effective IoT-based flow tuning relies on several interconnected technological layers that work together to create a responsive ecosystem. At the foundation sit the sensors themselves—small, intelligent devices capable of measuring temperature, pressure, flow rate, vibration, chemical composition, and dozens of other critical parameters. These sensors represent the eyes and ears of your operation, constantly gathering data points that inform decision-making processes.

The Sensor Network Architecture

Modern IoT deployments utilize mesh networks that allow sensors to communicate with each other and with central processing units through multiple pathways. This redundancy ensures that data flows continuously even if individual connection points fail. Sensors typically connect via protocols like MQTT, CoAP, or proprietary industrial standards, transmitting data packets at intervals ranging from milliseconds to minutes depending on the application’s criticality.

Edge computing devices serve as intermediate processing nodes, performing preliminary analysis on sensor data before transmitting condensed insights to cloud platforms. This architecture reduces bandwidth requirements, minimizes latency, and enables split-second decision-making when immediate action is necessary to prevent equipment damage or quality issues.

Data Processing and Analytics Engines

The raw data generated by IoT sensors becomes valuable only when properly analyzed and contextualized. Advanced analytics platforms employ machine learning algorithms that recognize patterns, predict equipment failures before they occur, and identify optimization opportunities that human operators might overlook. These systems continuously learn from historical data, improving their predictive accuracy and recommendation quality over time.

Stream processing technologies like Apache Kafka, Apache Flink, and AWS Kinesis handle the massive volumes of data generated by industrial IoT deployments, processing thousands of events per second and triggering automated responses when specific conditions are detected. This real-time processing capability forms the backbone of effective flow tuning systems.

💡 Practical Applications Across Industries

The versatility of IoT flow tuning extends across numerous sectors, each benefiting from customized implementations that address specific operational challenges. Understanding these practical applications helps organizations identify opportunities within their own operations and build business cases for IoT investments.

Manufacturing Excellence Through Precision Control

Manufacturing facilities have emerged as prime beneficiaries of real-time flow tuning technology. In chemical processing plants, IoT sensors monitor reactant flow rates, temperatures, and pressures, automatically adjusting values to maintain optimal reaction conditions. This precision prevents batch failures, reduces raw material waste, and ensures consistent product quality that meets stringent specifications.

Automotive assembly lines use IoT systems to regulate paint application rates, curing temperatures, and robotic movement speeds based on environmental conditions and material properties. When humidity levels rise, the system automatically compensates by adjusting paint viscosity and application parameters, maintaining finish quality without manual intervention or production delays.

Energy Sector Optimization

Power generation and distribution networks represent critical infrastructure where efficiency improvements yield enormous economic and environmental benefits. Smart grid implementations use IoT sensors throughout transmission networks to balance loads dynamically, route power along optimal pathways, and prevent overloads that could trigger blackouts.

Renewable energy installations particularly benefit from real-time flow tuning. Wind farms adjust turbine blade angles based on instantaneous wind speed and direction data, maximizing energy capture while preventing mechanical stress that shortens equipment lifespans. Solar installations optimize inverter performance and tracking system positioning to extract maximum power output throughout changing weather conditions.

Water Management and Distribution

Municipal water systems leverage IoT flow tuning to detect leaks, maintain optimal pressure throughout distribution networks, and balance supply across demand zones. Sensors positioned at strategic points monitor flow rates, pressure levels, and water quality parameters, alerting operators to anomalies that could indicate infrastructure failures or contamination events.

Agricultural irrigation systems represent another compelling application where real-time tuning delivers substantial value. Soil moisture sensors, weather stations, and plant health monitors work together to deliver precisely calibrated water volumes to different crop zones, reducing water consumption by 30-50% while improving yields through optimized growing conditions.

🔧 Implementation Strategies for Maximum Impact

Successfully deploying IoT flow tuning systems requires careful planning, phased execution, and ongoing refinement. Organizations that approach implementation strategically realize benefits faster and avoid common pitfalls that derail less thoughtful deployments.

Assessment and Planning Phase

Begin by conducting thorough assessments of existing processes to identify flow control points where real-time tuning would deliver the greatest value. Look for operations with high variability, significant waste generation, quality control issues, or energy-intensive processes. These represent prime candidates where IoT interventions generate measurable returns on investment.

Develop clear key performance indicators (KPIs) that will measure success. Avoid vague metrics in favor of specific, quantifiable targets such as reducing energy consumption by 15%, decreasing defect rates by 25%, or improving throughput by 20%. These concrete goals guide technology selection and provide benchmarks for evaluating performance post-deployment.

Technology Selection and Integration

Choose sensors and platforms that align with your operational environment and technical requirements. Industrial settings may require ruggedized sensors with explosion-proof ratings, while office environments can utilize consumer-grade devices. Consider factors like communication range, battery life, data accuracy, calibration requirements, and compatibility with existing systems.

Integration with legacy equipment often presents significant challenges. Modern IoT platforms offer various approaches including retrofitting existing sensors with wireless transmitters, installing parallel monitoring systems, or gradually replacing aging equipment with IoT-enabled alternatives. Select the approach that balances cost, disruption, and technical feasibility within your specific context.

Pilot Programs and Scaling

Launch pilot programs in controlled environments where you can validate technology performance, refine algorithms, and build organizational confidence before broader deployment. Choose pilot locations that represent typical operating conditions while remaining accessible for troubleshooting and adjustment during the learning phase.

Document lessons learned throughout pilot programs, capturing both technical insights and organizational change management observations. This knowledge accelerates subsequent deployments and helps avoid repeating mistakes as you scale across additional facilities or process lines.

📊 Measuring and Optimizing Performance

Implementing IoT flow tuning represents just the beginning of an optimization journey. Continuous measurement, analysis, and refinement ensure that systems deliver sustained value and adapt to evolving operational requirements.

Establishing Baseline Metrics

Before implementing real-time tuning, establish comprehensive baseline measurements of current performance across all relevant dimensions. Document energy consumption patterns, material waste rates, throughput volumes, quality metrics, and maintenance requirements under existing operating procedures. These baselines provide the foundation for calculating return on investment and validating improvement claims.

Continue collecting comparable metrics after implementation to track performance trends over time. Look for improvements not only in primary targets but also in secondary benefits like reduced maintenance requirements, extended equipment lifespans, and improved worker safety that may not have been primary implementation drivers but deliver substantial value nonetheless.

Advanced Analytics and Continuous Improvement

Leverage the rich data streams generated by IoT systems to uncover deeper optimization opportunities through advanced analytics. Apply machine learning techniques to identify non-obvious correlations between variables, predict optimal parameter settings for different operating scenarios, and detect gradual equipment degradation before it impacts performance.

Establish regular review cycles where cross-functional teams analyze performance data, share observations, and propose refinements to tuning algorithms or operational procedures. This collaborative approach ensures that technical capabilities align with practical operational knowledge, maximizing the effectiveness of automated systems while maintaining appropriate human oversight.

🔐 Security and Reliability Considerations

As industrial systems become increasingly connected and automated, security and reliability emerge as paramount concerns that must be addressed proactively throughout design, implementation, and operation phases.

Cybersecurity Best Practices

Protect IoT networks through multiple security layers including network segmentation, encrypted communications, strong authentication mechanisms, and regular security audits. Isolate operational technology networks from corporate IT systems to prevent malware or attacks from spreading between domains. Implement zero-trust architectures that verify every connection attempt rather than assuming internal network traffic is inherently trustworthy.

Regular firmware updates and security patches represent critical maintenance activities that prevent exploitation of known vulnerabilities. Establish update management procedures that balance security needs against operational stability requirements, testing updates in non-production environments before deploying to critical systems.

Ensuring System Reliability

Design IoT flow tuning systems with redundancy and failsafe mechanisms that maintain safe operation even when components fail. Critical control points should include manual override capabilities that allow operators to assume direct control if automated systems malfunction. Build graceful degradation into system architecture so that partial sensor failures result in conservative operating modes rather than complete shutdowns.

Regular testing of backup systems, disaster recovery procedures, and failover mechanisms ensures that reliability protections function correctly when needed. Schedule these tests during planned maintenance windows and document outcomes to continuously improve resilience capabilities.

The Economic Case for Real-time Flow Tuning

While technical capabilities drive interest in IoT flow tuning systems, financial considerations ultimately determine implementation decisions. Building compelling business cases requires quantifying both direct cost savings and less tangible strategic benefits.

Calculating Return on Investment

Direct cost savings typically come from reduced energy consumption, decreased material waste, improved labor productivity, and lower maintenance expenses. Energy savings alone often justify IoT investments, particularly in energy-intensive industries where real-time optimization can reduce consumption by 10-30%. Material waste reductions similarly deliver immediate bottom-line impact, especially in operations processing expensive raw materials.

Indirect benefits include improved product quality that commands premium pricing, enhanced regulatory compliance that avoids penalties, increased throughput that enables revenue growth without capital expansion, and improved customer satisfaction through consistent delivery performance. While harder to quantify precisely, these strategic advantages often exceed direct cost savings in total value contribution.

Risk Mitigation Value

Real-time monitoring and flow tuning significantly reduce operational risks including equipment failures, safety incidents, environmental releases, and quality defects. Quantify these risk reductions by calculating the probability and potential cost of adverse events under current operations versus IoT-enabled scenarios. Even modest reductions in catastrophic failure risks justify substantial investments when potential consequences include injuries, environmental damage, or facility shutdowns.

🌟 Future Trends and Emerging Capabilities

The evolution of IoT technology continues accelerating, bringing new capabilities that will further enhance real-time flow tuning effectiveness in coming years. Organizations planning IoT investments should consider these emerging trends to ensure their implementations remain relevant and can incorporate future innovations.

Artificial intelligence and machine learning algorithms are becoming increasingly sophisticated, enabling predictive optimization that anticipates future conditions and adjusts flows proactively rather than reactively. Digital twin technology creates virtual replicas of physical systems where operators can test optimization strategies in simulated environments before deploying to production equipment.

5G networks and edge computing architectures dramatically reduce latency between sensor data collection and automated responses, enabling real-time control of processes that require millisecond-level precision. Quantum computing promises to solve optimization problems of unprecedented complexity, potentially unlocking efficiency improvements currently beyond reach of classical computing approaches.

Sustainability imperatives are driving innovation in IoT applications focused specifically on reducing environmental impacts. Carbon tracking systems integrate with flow tuning platforms to minimize emissions while maintaining production targets. Water conservation capabilities become increasingly sophisticated as scarcity challenges intensify globally.

Building Organizational Capabilities for Success

Technology alone cannot deliver the full potential of IoT flow tuning systems. Organizations must develop complementary human capabilities, cultural attributes, and operational processes that enable effective technology utilization.

Invest in training programs that develop workforce skills in data analysis, IoT system operation, and continuous improvement methodologies. Cross-train personnel so that operations staff understand technology capabilities while IT professionals appreciate operational requirements and constraints. This shared knowledge foundation enables more effective collaboration and faster problem resolution.

Foster a culture of experimentation where teams feel empowered to test new optimization approaches, learn from failures, and continuously challenge existing practices. Celebrate improvements regardless of size and share learnings across organizational boundaries to accelerate collective capability development.

Establish governance frameworks that balance automation with human judgment, defining clear decision rights for different scenarios. Specify when automated systems should operate autonomously, when they should recommend actions for human approval, and under what circumstances manual override becomes necessary. These frameworks provide clarity while maintaining appropriate oversight of critical processes.

The transformative potential of real-time flow tuning with IoT systems extends across virtually every industry sector, offering unprecedented opportunities to maximize efficiency, reduce waste, and optimize performance. Organizations that strategically implement these technologies while developing complementary organizational capabilities position themselves to thrive in increasingly competitive and resource-constrained operating environments. Success requires thoughtful planning, phased execution, continuous refinement, and unwavering commitment to both technological excellence and human development.

Toni Santos is a systems researcher and aquatic bioprocess specialist focusing on the optimization of algae-driven ecosystems, hydrodynamic circulation strategies, and the computational modeling of feed conversion in aquaculture. Through an interdisciplinary and data-focused lens, Toni investigates how biological cycles, flow dynamics, and resource efficiency intersect to create resilient and productive aquatic environments. His work is grounded in a fascination with algae not only as lifeforms, but as catalysts of ecosystem function. From photosynthetic cycle tuning to flow distribution and nutrient conversion models, Toni uncovers the technical and biological mechanisms through which systems maintain balance and maximize output with minimal waste. With a background in environmental systems and bioprocess engineering, Toni blends quantitative analysis with ecological observation to reveal how aquatic farms achieve stability, optimize yield, and integrate feedback loops. As the creative mind behind Cynterox, Toni develops predictive frameworks, circulation protocols, and efficiency dashboards that strengthen the operational ties between biology, hydraulics, and sustainable aquaculture. His work is a tribute to: The refined dynamics of Algae Cycle Optimization Strategies The precise control of Circulation Flow and Hydrodynamic Systems The predictive power of Feed-Efficiency Modeling Tools The integrated intelligence of Systemic Ecosystem Balance Frameworks Whether you're an aquaculture operator, sustainability engineer, or systems analyst exploring efficient bioprocess design, Toni invites you to explore the operational depth of aquatic optimization — one cycle, one flow, one model at a time.